Product classification

Contact Us

Advisory Hotline

Contact: Cai Min 139 1708 3595

Contact: Mao Haifeng 189 7586 1610

Mailbox:record@lkd-record.com

Product Center

LF 401 is a spraying film which used for waterproofing to concrete structures. It is mainly used for spraying construction between shotcrete or cast-in-place concrete to make a "sandwich". It has good bond strength and elasticity between the two concrete. As a bonding entity, it provides excellent waterproofing properties for underground structures to prevent water ingress. LF 401 will get hardened within 4 to 6 hours (depending on environmental conditions) after spraying off, providing sufficient time for concrete lining and effectively ensuring construction progress. Similar to other shotcrete products, it can not prevent water penetration through the concrete. For such cases, it will be better to start spraying after water drainage. (Please refer to the LF 401 technical description. However, the LF 401 can be used in humid working (Non flowing water) surfaces. LF401 is also suitable for steel fiber shotcrete structures.)

LG 131 is a two-component solvent-free resin foam suitable for rapid filling of cavities in coal mine tunnel and rock face, water proofing and prevention of air leakage.

LC 241 is a two-component injection foam used for cavity filling, to isolate air and mash-gas intervention.

LG 131 is a solvent-free silicate modified polyurethane resin made of two-component which use for grouting and rapid treatment of fractured coal mine layer and rock fault.

LG 134 is polyurethane material made of two-component, which use for ground reinforcement and small water ingress. It has high level adhesive force and excellent mechanical properties. It can last the same long lifetime when bonding and united with the ground condition; The reaction speed of the product can be improved by adding a certain amount of accelerator. After injection into the ground, the low-viscosity mixture remains as liquid status for a few seconds, penetrates into cracks, expands, and effectively strengthens and seals the broken area.

LD 332 is a kind of one-component polymer water plugging material formed by chemical reaction of isocyanate and water-soluble polyether.

LD 331 is a two-component polyurethane polymer used for waterproof and rock reinforcement. Its high performance of adhesive force and good mechanical and physical properties ensure that it has strong bonding with rock mass. The reaction will expand when it meets water, quickly and effectively to prevent water ingress. Its flexibility can bear the ground movement; Moreover, it has strong anti-permeability, anti-wear, anti-impact and anti-aging properties, so as to achieve the purpose of long-term stable formation, sealing water cracks and channels.

LD 333 is a kind of one-component polymer water plugging material formed by chemical reaction of isocyanate and polyether.

LD 334 rescue polyurethane grouting material usually made of main agent and catalyst with ratio matching of 8:1 or 10:1. It is a kind of polymer chemical grouting material which is specially used in the process of metro line tunnel and shaft excavation, in case of emergency water ingress. The material reacts immediately with water and expands rapidly in volume.

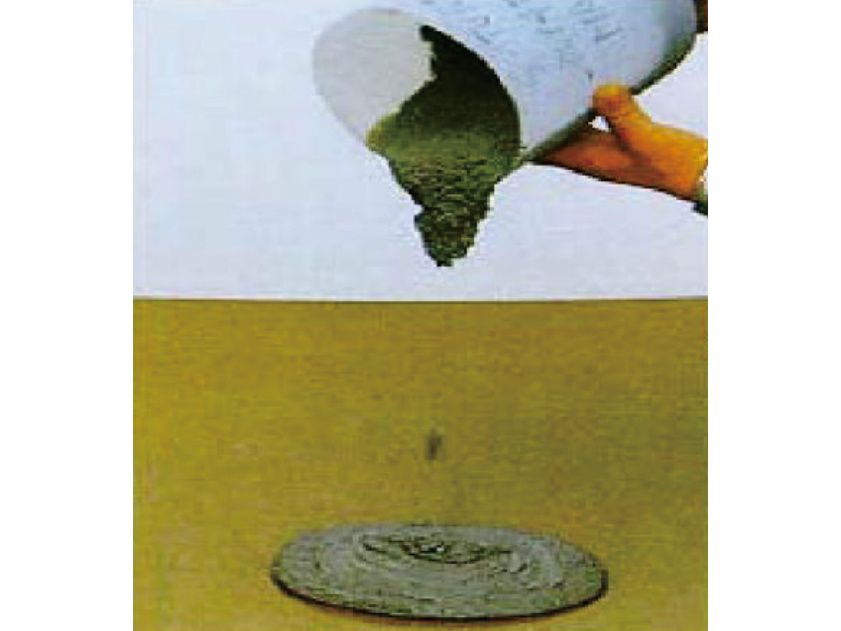

LZ 701 is composed of inorganic material, which can be used for high strength grouting material; The product is a powder compound grouting material. After mixing with water, it forms a kind of grouting material with shrinkage compensation and thixotropy. The compressive strength and fluidity can be adjusted by modifying the water-cement ratio during pulping. It is a composite product in environmental safety, strong environmental adaptability, early strength and late strength are high.

PA is formulated as a first fill grade tail sealant to be used on shielded tunnel boring machines(TBM).Together with the wire brushes, the sealant forms an impermeable barrier between the tail

shield of the TBM and the concrete segments to effectively seal off any ingress of water, soil and annulus grout/mortar back into the TBM invert.

HBW is a clay thickened lubricating grease for lips sealing system of TBM main bearing, which is based on mineral oil and polymers. The grease contains a selection of solids, fibers and graphite. It effectively protects the main bearing by preventing the ingress of soil, water or dust through the main bearing sealing.